The Essential Role of Precision Mould Part Manufacturers in Today’s Industry

We have every reason to believe. precision plastic mould components It will become the mainstream of the industry and will gradually affect more and more people. https://www.dghrjmmj.com

In the rapid-paced industrial environment we face today, precision mould part manufacturers are vital contributors. Their specialization and skilled craftsmanship are critical in delivering high-quality mould components needed to meet the demanding standards of sectors such as automotive, aerospace, electronics, and medical devices. This blog post highlights the significance of precision mould part manufacturers, the key processes involved in their operations, and the influence they exert on contemporary manufacturing.

The Importance of Precision Mould Part Manufacturers

Precision mould parts are crucial in producing a wide array of everyday products. These components are essential for ensuring that moulds work efficiently, enabling large-scale manufacturing with consistent levels of quality and exact specifications. Manufacturers of precision mould parts craft these vital components according to precise standards, making sure each piece meets necessary size and tolerance requirements.

cusotomized precision mold components factory.png

Key Processes in Precision Mould Part Manufacturing

1. Design and Engineering: The process begins with detailed design and precise engineering. Manufacturers collaborate closely with clients to grasp their specific needs and develop intricate blueprints. Advanced CAD software is typically utilized to simulate and fine-tune designs prior to production.

2. Material Selection: Optimal material choice is vital for mould part performance and endurance. Manufacturers choose materials based on criteria including strength, durability, thermal conductivity, and resistance to wear and corrosion.

3. Precision Machining: With the design set in place, precision machining becomes the focus. Employing cutting-edge CNC machinery, manufacturers intricately form raw materials into exact mould components. This procedure demands remarkable skill and immense attention to achieve the specified precision.

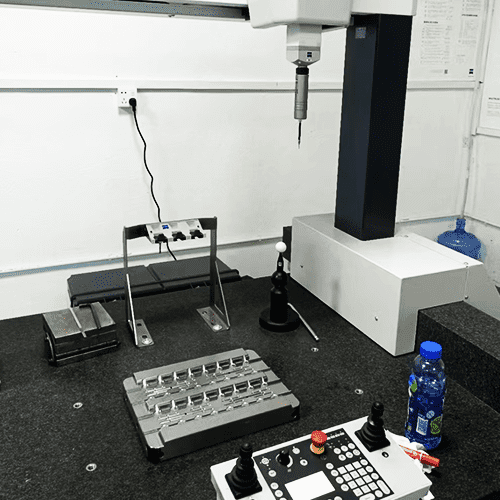

4. Quality Control: Comprehensive quality control protocols are enforced throughout production. Manufactures utilize advanced inspection techniques and equipment, such as coordinate measuring machines (CMM) and optical comparators, verifying each part meets exact tolerances and dimensions.

5. Surface Treatment: To further enhance components’ performance and longevity, mould parts often undergo treatments such as polishing, coating, or hardening, reducing friction, increasing resistance to wear, and prolonging component life.

precision mould part manufacturer.png

The Impact on Modern Manufacturing

Precision mould part manufacturers fundamentally contribute to innovation and efficiency in today’s manufacturing fields. Their expertise allows various industries to fabricate intricate components with high degrees of precision and consistency, an ability crucial in domains like automotive and aerospace where minute discrepancies can cause considerable repercussions.Furthermore, these manufacturers assist companies by maximizing cost-effectiveness and minimizing time-to-market through dependable parts that lessen the likelihood of downtime and minimize the necessity for upkeep. Their proficiency also accelerates new product development with the capability for swift prototyping and assessment.