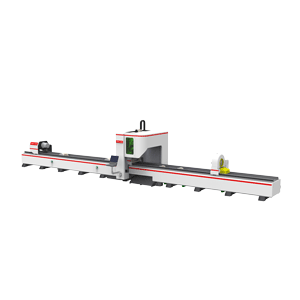

Laser cutting machine in the intelligent manufacturing road of agricultural machinery industr

With the accelerated advancement of agricultural modernization, the agricultural machinery industry is undergoing unprecedented changes. In this change, intelligent manufacturing technology has become a key force in promoting the upgrading of the agricultural machinery industry. Among them, laser cutting machine, as one of the important equipment for intelligent manufacturing, plays an increasingly important role in the intelligent manufacturing road of agricultural machinery industry. This article will deeply explore the application status, advantages and future development trends of laser cutting machine in the agricultural machinery industry, aiming to provide a useful reference for the intelligent manufacturing of agricultural machinery industry.Actually, it’s not just this reason, laser cut machine Its own advantages are also obvious, and it is normal for the market to perform well. https://www.cnyoniklaser.com/

?Laser cutting machine in the intelligent manufacturing road of agricultural machinery industry?

1. Application status of laser cutting machine in agricultural machinery industry

In the agricultural machinery industry, laser cutting machine has been widely used in the manufacturing process of various agricultural machinery products. From tractors, harvesters to seeders and other agricultural machinery, laser cutting machine plays an important role. It can not only achieve efficient and precise cutting of metal sheets, but also meet the needs of agricultural machinery products for complex shapes and fine structures. In addition, laser cutting machine has also shown unique advantages in parts processing, proofing testing and small batch production in the agricultural machinery industry.

2. Advantages of laser cutting machines in the agricultural machinery industry

?Improve production efficiency?: With its high-speed and high-precision cutting capabilities, laser cutting machines have significantly improved the production efficiency of agricultural machinery products. Compared with traditional cutting methods, laser cutting does not require molds, which reduces production preparation time, and can achieve continuous processing, greatly shortening the production cycle.

?Reducing costs?: During the cutting process, laser cutting machines do not require tools to contact materials, reducing material waste and tool consumption, and reducing production costs. In addition, laser cutting machines can also achieve cutting of complex shapes, reducing subsequent processing steps, and further reducing production costs.

?Improve product quality?: The parts cut by laser cutting machines are of high precision and smooth edges, and can meet the manufacturing requirements of agricultural machinery products without secondary processing. This not only improves the appearance quality of the product, but also enhances the durability and reliability of the product.

3. Intelligent manufacturing practice of laser cutting machines in the agricultural machinery industry

In the intelligent manufacturing practice of the agricultural machinery industry, laser cutting machines are combined with other intelligent manufacturing equipment to form a complete intelligent manufacturing production line. By introducing advanced control systems and sensor technologies, laser cutting machines can achieve seamless docking and collaborative operation with upstream and downstream equipment. This not only improves the automation level of the production line, but also realizes real-time monitoring and precise control of the production process. In addition, the laser cutting machine can also be customized according to customer needs, meeting the needs of the agricultural machinery industry for diversified and personalized products.

4. Future development trend of laser cutting machine in the agricultural machinery industry

With the accelerated advancement of agricultural modernization and the continuous development of intelligent manufacturing technology, the future development trend of laser cutting machine in the agricultural machinery industry will show the following characteristics:

?Technology continues to innovate?: With the continuous advancement and innovation of laser technology, the performance of laser cutting machine will continue to improve. In the future, laser cutting machine will achieve higher cutting accuracy and speed, while reducing energy consumption and emissions, and realizing a more environmentally friendly and energy-saving production method.

?Application scope continues to expand?: With the increasing demand for intelligent manufacturing technology in the agricultural machinery industry, the application scope of laser cutting machine will continue to expand. In the future, laser cutting machine will not only be used in the cutting and processing of metal sheets, but will also be expanded to non-metallic materials, composite materials and three-dimensional cutting.

?Intelligence level continues to improve?: With the continuous introduction and application of advanced technologies such as artificial intelligence and the Internet of Things, laser cutting machine will achieve a more intelligent production method. In the future, laser cutting machines will be able to adaptively adjust and optimize cutting parameters according to production needs, achieving a more efficient and precise production process.

V. Summary and Outlook

?Laser cutting machine in the intelligent manufacturing road of agricultural machinery industry?

As one of the important equipment for intelligent manufacturing, laser cutting machines are playing an increasingly important role in the intelligent manufacturing of the agricultural machinery industry. By improving production efficiency, reducing costs, and improving product quality, laser cutting machines provide strong support for intelligent manufacturing in the agricultural machinery industry. In the future, with the continuous innovation of technology and the continuous expansion of its application scope, laser cutting machines will play a more important role in the agricultural machinery industry, promoting the agricultural machinery industry to develop in a more intelligent, efficient, and green direction.