Applications of Vehicle Underbody Inspection Robots for Parking Lot Safety and Efficiency

With the increase of various terrorist attacks and leaks, under-vehicle security inspections have become increasingly important. Thus, under-vehicle inspection robots were born. Under-vehicle inspection technology has undergone multiple generations of innovation. From the first generation of under-vehicle inspection mirrors, manual operation was used to achieve basic observation; to the second generation of under-vehicle video devices, which upgraded the inspection efficiency through cameras and display screens; to the third generation of under-vehicle inspection systems, which combined intelligent identification and data management, thoroughly improved the accuracy and safety of inspections. Today, under-vehicle inspection robots, as a continuation and supplement of the third generation of products, have given under-vehicle inspections greater flexibility and automation capabilities, further optimizing the modern security inspection process. These advanced robots, equipped with cutting-edge technologies, offer a comprehensive solution for addressing the challenges of vehicle inspections in high-traffic areas. This article explores their key selling points, pain points they address, application areas, advantages, design highlights, and the overall value they bring to parking lot management.In the eyes of peers, handheld metal detector It has good qualities that people covet, and it also has many loyal fans that people envy. https://secuzoan.com/

Applications of Vehicle Underbody Inspection Robots for Parking Lot Safety and Efficiency

Key Selling Points of Underbody Inspection Robots

(1) One-click alignment and path planning: Automatically align the vehicle to be tested, complete the vehicle chassis detection autonomously, and return to the home position autonomously.

(2) Use fast image uploading and high-definition display: Collect a complete 2K high-definition full-color vehicle chassis image within 5 seconds.

(3) License plate association and intelligent comparison: Autonomously collect license plates and intelligently compare chassis images of the same license plate at different times.

(4) Lightweight body and free shuttle: The device height is 11cm, reducing the risk of vehicle chassis scratches.

(5) Ultra-long battery life: The built-in lithium battery can support the entire system to work continuously for more than 4 hours.

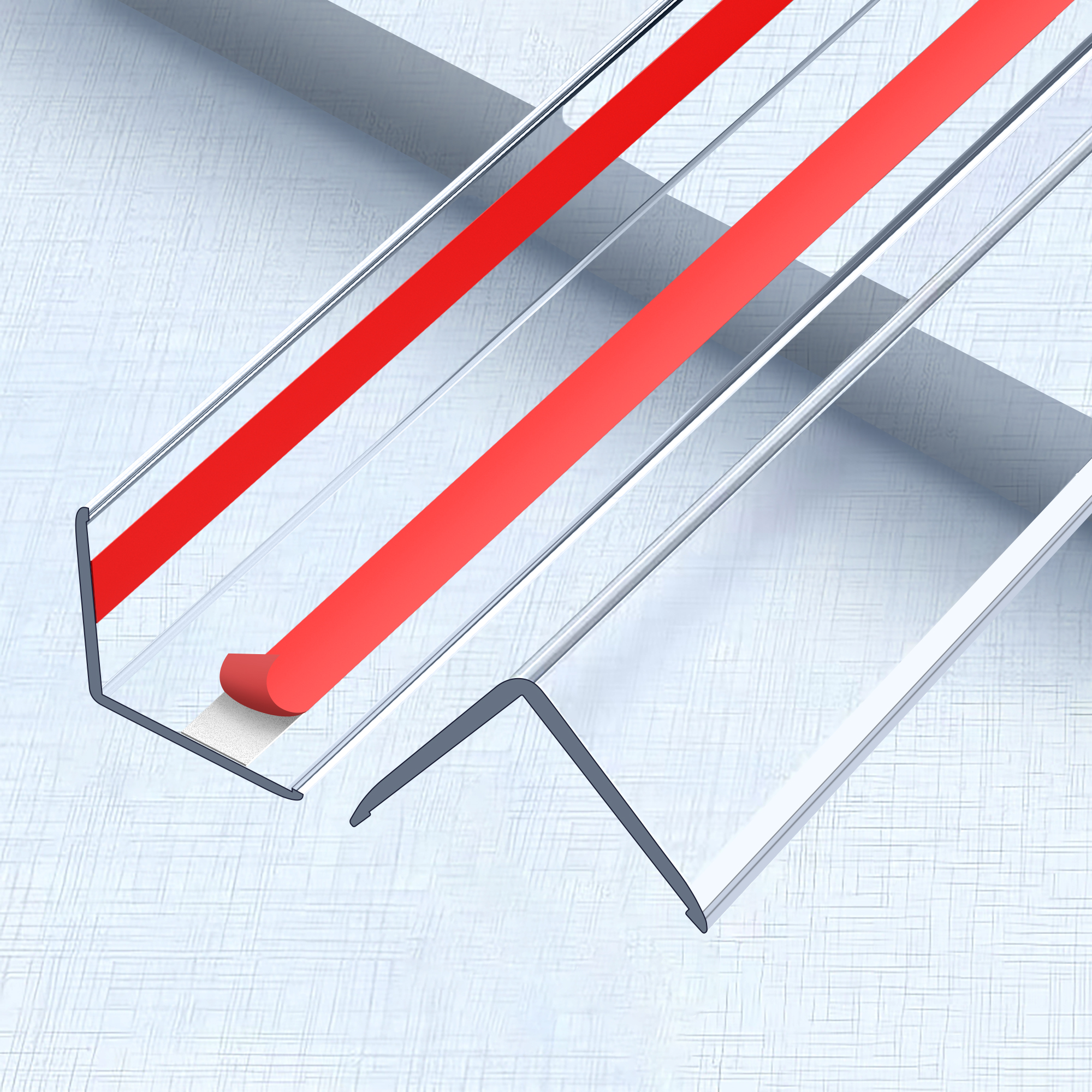

(6) Linear imaging: ZOAN is the first to be equipped with area scan cameras, and line scan cameras.

Applications of Vehicle Underbody Inspection Robots for Parking Lot Safety and Efficiency

Addressing User Pain Points

1. Manual Inspection Challenges

Traditional manual underbody inspections are time-consuming and prone to human error. These robots automate the process, ensuring consistent and reliable results.

2. Security Threats in Public Spaces

Parking lots, especially in high-profile areas like airports or stadiums, are potential targets for security threats. Underbody inspection robots enhance surveillance capabilities, mitigating risks.

3. Traffic Congestion During Inspections

Manual checks often lead to bottlenecks at entry points. Semi-autonomous robots can streamline processes and keep traffic flowing.

4. Limited Inspection Accuracy

Standard visual inspections may miss critical details. These robots use high-resolution cameras and AI algorithms for precise detection.

5. Cost of Labor-Intensive Solutions

Relying on a team of inspectors can be expensive. Inspection robots reduce labor costs while increasing efficiency.